| Model | Max Feed Size (mm) | Output size (mm) | Capacity (t/h) | Rotating speed (r/min) | Power (kW) | Weight (t) | Overall Dimension (mm) |

| PE250x400 | 200 | 20-50 | 5-15 | 300 | 15 | 3 | 1430x1310x1340 |

| PE400x600 | 350 | 40-100 | 15-60 | 275 | 30-37 | 7 | 1700x1732x1653 |

| PE500x750 | 425 | 50-100 | 40-110 | 275 | 45-55 | 12 | 2035x1921x2000 |

| PE600x900 | 480 | 65-160 | 90-180 | 250 | 55-75 | 17 | 2290x2206x2370 |

| PE750x1060 | 630 | 80-140 | 110-320 | 250 | 90-110 | 29 | 2655x2302x3110 |

| PE900x1200 | 750 | 95-165 | 220-450 | 200 | 110-132 | 58 | 3800x3166x3045 |

| PE1000x1200 | 850 | 200-300 | 280-560 | 200 | 110-160 | 69 | 5350x4280x3050 |

| PEX150x750 | 125 | 18-48 | 10-25 | 320 | 15 | 3.8 | 1200x1500x1200 |

| PEX250x750 | 210 | 25-60 | 15-30 | 330 | 22-30 | 5 | 1667x1545x1020 |

| PEX250x1000 | 210 | 25-60 | 15-50 | 330 | 30-37 | 7 | 1550x1964x1380 |

| PEX250x1200 | 210 | 25-60 | 20-60 | 330 | 37-45 | 8.5 | 2192x1900x1950 |

- Home

- Products

- River pebble granite jaw crusher construction waste diesel engine movable jaw crusher sand making machine

River pebble granite jaw crusher construction waste diesel engine movable jaw crusher sand making machine

Get top-quality River pebble granite jaw crusher, construction waste diesel engine movable jaw crusher, and sand making machine from our factory. Efficient and durable machines for all your crushing and sand-making needs. Order now!

Request a QuotePRODUCTS DETAILS

Hot Products

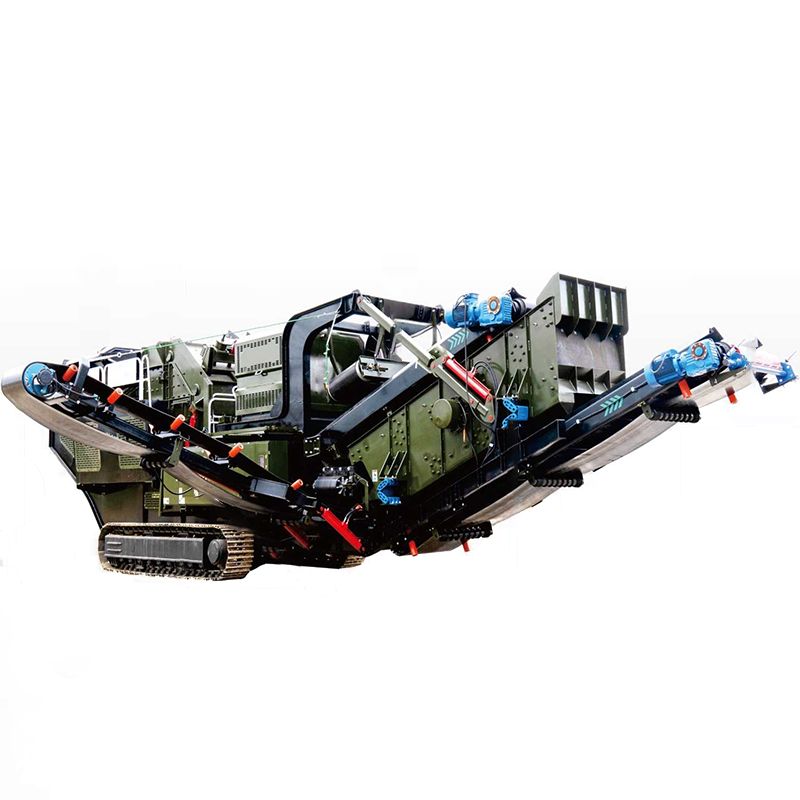

Crawler Type Mobile Impact Crusher/TP-1380A/TP-1380B/TP-1380C/TP-1520A/TP-1520B

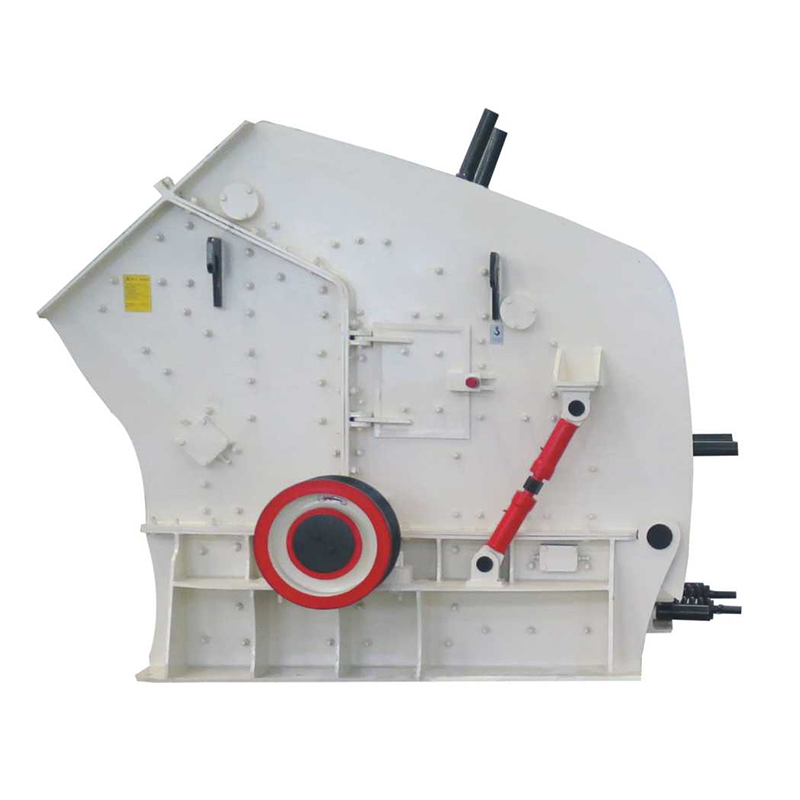

Impact Crusher Stone Production Line Large inlet Impact Crusher Stone Shaping Three-Cavity Impact Crusher

Hard Rock Cone Crusher Cobblestone Iron Ore Crusher Quartz Stone Cone Crusher

Crawler-type mobile small jaw crushing station (with generator set) oil-electric dual-purpose/TP-57/TP-106(75)

Crawler Mobile Cone Crusher/TP-HP300

Crawler Type Mobile Inclined Screening Plant/TP-6518/TP-7018/TP-6200/TP-500

River pebble granite jaw crusher construction waste diesel engine movable jaw crusher sand making machine

ZSW vibration feeder motor vibration feeder electromagnetic vibration feeder vibration feeder feeder feeder

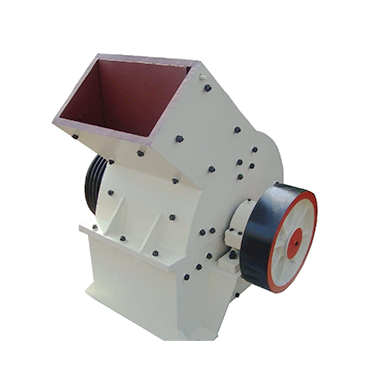

Small mobile sand making machine building demolition site hammer crusher cement block granite sand making machine

Stone vibrating screen factory direct sale of quartz limestone YK YA type screening stone vibrating screen

Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours